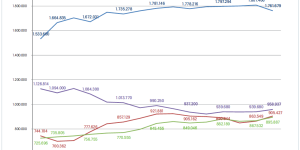

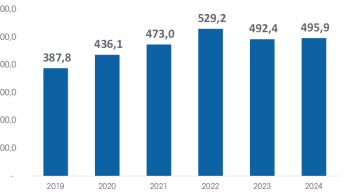

Karl Morris is keen to start a discussion almost before the press representative has entered the room. This meeting with the managing director of the Canadian manufacturer Norbord is at one of the company’s eleven OSB production locations in Genk, Belgium, some 70 kilometres from Aachen. It doesn’t take long before Morris comes to the subject of safety. “This topic permeates every single operation in the company and in the management processes,” says Morris. A glance at one of the charts that the manager later projects onto the wall shows why. The table shows the accident rates at the works at the time of its acquisition. Norbord took over the Genk production location in 2005. By that stage the original owner family had failed to obtain a licence to operate any longer, partly because the strict safety standards could not be fulfilled. The chart’s blue and red bars show how many of the industrial accidents had to be reported and how many of them led to the loss of working hours.¹ Within just four years the new owner managed to bring this figure down to nil through a great variety of different measures. “Unfortunately the figures have risen again slightly in the meantime,” says Morris, “but we are working on that.” Precisely how seriously the safety precautions are taken at the plant is revealed upon arrival at the visitors’ parking area. The rule there is that everyone, employees as well as management and visitors, is only allowed to park backwards. The explanation: everyone must be able to leave the grounds as quickly as possible in case there is a fire. “Anyone failing to adhere to the safety regulations,” says Morris, “can leave the works again immediately, we are absolutely consistent here.” The clearly improved safety standards, together with enhanced in-house procedures and investment in the production facilities themselves, are the key reason behind Norbord’s ability to increase the productivity of the works by 55 per cent since 2005. “In the next few years we will attempt to further increase our output,” says Morris. The pre-condition for this is achieving the goal of keeping the facility running right round the clock throughout the entire year. And here again, as Morris confirms, we come back to the subject of safety once more. Morris does not doubt that the increased production will be absorbed by the market. “With OSB we are still dealing with a growth product.” So he reckons on consumption continuing to increase considerably, especially in…

Growth product OSB

Norbord operates one of its OSB plants in Genk, Belgium. Safety is one of the central factors in the production process

Menü

Menü

Newsletter

Newsletter